Cheap Price Mobile Concrete Mixing Plant Equipment Customization

Affordable, Custom Mobile Concrete Mixing Solutions That Solve Real Operational Challenges

1. Pain-Point Driven Opening

Commercial concrete producers and contractors face persistent challenges with mobile mixing plants:

- High Capital Costs: Budget constraints limit access to flexible batching solutions, forcing reliance on outdated or inefficient setups.

- Downtime Losses: Static plants require 30–50% more time for relocation, costing $1,200+ per idle hour in lost production.

- Inflexible Configurations: Standard models fail to adapt to varying project specs, wasting materials and labor.

- Maintenance Complexity: Poorly designed systems increase service intervals by 25%, adding $8,000+/year in unplanned repairs.

What if your mobile plant could reduce setup time by 40%, cut fuel consumption by 15%, and scale output precisely to demand—without upfront overinvestment?

2. Product Overview: Cheap Price Mobile Concrete Mixing Plant Equipment Customization

A modular, trailer-mounted batching system designed for rapid deployment and tailored production:

- Site Setup: Hydraulic outriggers stabilize the unit in <30 minutes on uneven terrain.

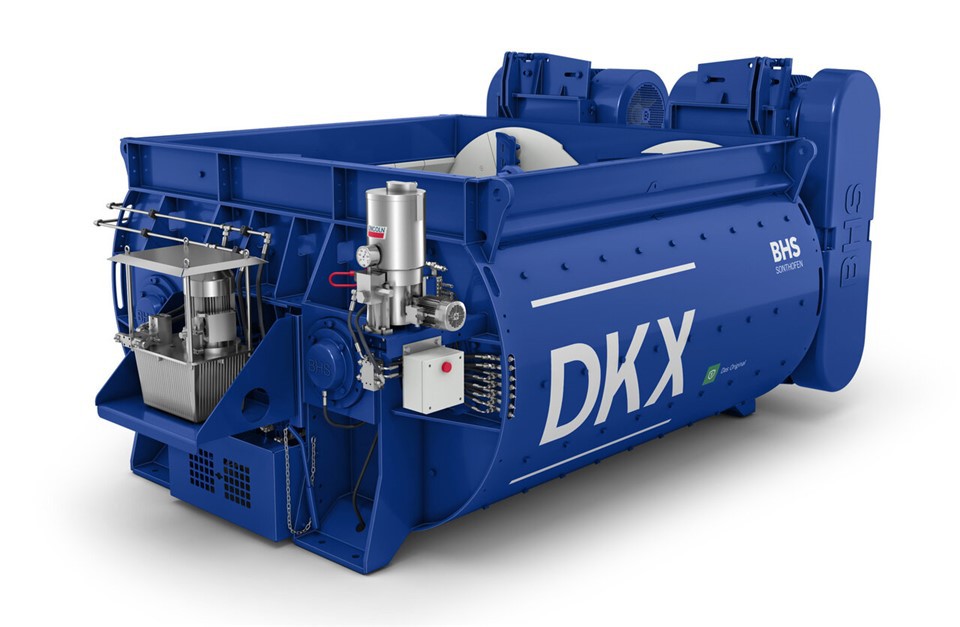

- Material Loading: Aggregate bins and cement silos feed a twin-shaft mixer via automated weigh bridges (±0.5% accuracy).

- Mixing & Discharge: High-torque mixing ensures homogeneous concrete in 45–60 seconds; discharge height adjusts from 3.8m–4.5m for direct truck loading.

Best For: Roadwork, remote projects, RMC producers needing temporary capacity expansion.

Limitations: Not suitable for continuous >120 m³/hr production; requires flat ground (<5° slope).

3. Core Features

Modular Frame Design | Technical Basis: ISO-certified steel construction | Operational Benefit: 60% faster assembly vs. welded frames | ROI Impact: Saves $4,500+ per relocation

Precision Batching System | Technical Basis: Load cell + PLC control | Operational Benefit: Reduces material waste by 3–5% | ROI Impact: Cuts $12/ton in cement overuse

Fuel-Efficient Drive | Technical Basis: Tier 4 diesel/Electric hybrid option | Operational Benefit: Lowers fuel costs by 18% | ROI Impact: Saves $9,600/year (300 operating days)

Customizable Output | Technical Basis: Interchangeable mixer drums (0.5–3 m³) | Operational Benefit: Matches output to project needs | ROI Impact: Eliminates 20% overproduction losses

Low-Maintenance Wear Parts | Technical Basis: Hardox 450 liners | Operational Benefit: Doubles component lifespan | ROI Impact: Reduces spare parts spend by $3,200/year

4. Competitive Advantages

| Performance Metric | Industry Standard | Our Solution | Advantage (%) |

|---|---|---|---|

| Relocation Time | 8–12 hours | <5 hours | -58% |

| Mixing Cycle Consistency | ±2% variance | ±0.8% variance | +60% accuracy |

| Energy Use per m³ | 4.2 kWh/m³ | 3.5 kWh/m³ | -17% |

| Customization Lead Time | 12–16 weeks | 6–8 weeks | -50% |

5. Technical Specifications

- Capacity: 25–90 m³/hr (configurable)

- Power: 55 kW electric or 74 HP diesel

- Materials: Aggregates ≤80mm slump, fly ash/cement compatible

- Dimensions: Transport mode – L12m x W2.5m x H3.2m

- Operating Range: -20°C to +50°C; IP54-rated controls

6.Application Scenarios

[Highway Contractor] Challenge: Needed intermittent batching across multiple sites with tight budgets ($250k CAPEX limit). Solution: Deployed customized Cheap Price Mobile Concrete Mixing Plant Equipment with quick-disconnect piping and a compact footprint. Results: Reduced mobilization costs by $18k/month vs rented plants; met variable demand (40–75 m³/day).**

[Ready-Mix Producer] Challenge: Seasonal demand spikes overwhelmed fixed plant capacity. Solution: Added two mobile units with silo extensions. Results: Increased peak output by 140 m³/day without permanent infrastructure; payback in <14 months**.

7.Commercial Considerations**

-Base Model Pricing: Starts at $95k (25 m³/hr) –$220k (90 m³/hr)

-Optional Features: Dust covers (+$6k), automated admixture dosing (+$9k), cold-climate kits (+$4k)

-Service Packages: Proactive maintenance contracts ($1